Brand name : O-DABPA 85%-90%

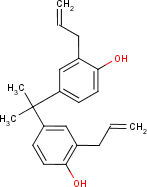

Chemical name : Phenol, 4,4'-(1-methylethylidene)bis(2-(2-propen-1-yl)- 2,2'

Synonym name : Diallylbisphenol A & D.B.A. & B.B.E.

CAS : 1745-89-7

EC number : 217-121-1

Structural formula :

Specifications

| Item |

Standard |

| Appearance |

Light yellow to brown liquid |

| Viscose |

300~1200cp |

| Purity acc. to HPLC |

|

Ortho-diallyl Bisphenol A (CAS no.

1745-89-7) |

90% min,85%min |

Usage

Diallyl bisphenol A/ diallyl bisphenol A ether is A modified monomer of thermosetting resins, which is mainly used in toughening bismaleimide resins, epoxy resins, phenolic resins, etc., which can greatly improve the toughness of thermosetting resins. It can also be used as an active thinner for thermosetting resins. Use in rubber can further improve the bonding strength between the metal.

The high performance resins system can be used for:

¢Ù Electrical insulation materials, copper coated circuit boards, high-temperature impregnated paint, insulating paint laminate, molded plastic and so on.

¢Ú wear-resistant materials, diamond grinding wheel, heavy load grinding wheel, brake plate, high-temperature bearing adhesive.

¢Û Aerospace structural materials.

¢Ü Functional materials. For rubber anti aging agents, the addition of 1-3 % BBA to rubber can greatly improve the aging resistance of rubber.

Applications

• As reactive diluents in combination with other bismaleimides

• Insulation resistant to high temperatures

• High-performance composites

• Adhesives and prepregs

Package

200Lplastic drum/1000L IBC drum

Storage

This material can be stable for 12 months under the normal storage conditions.However,precautions must be taken to avoid exposure to sunlight and always ,store this material in a sealed container under the dry and cool conditions.